Product Life Cycle from a CtoBEE perspective

From exemplary procedure to introduce CtoBEE to Mission Statement

One could compare the certification according to CtoBEE with the introduction of a new technology (such as computers). The core competence of the company is usually not in topics such as information processing, energy efficiency, ecology, climate change, etc.. This is not a disadvantage. On the contrary, with CtoBEE the company has the possibility to access the know-how externally. Linked with targets and joint projects, the company begins to pursue the ecological path. Not every company can afford to build up its own team for these topics. But without knowledge, it is probably no longer possible either. All topics related to ecology can be delegated to CtoBEE. And the company can focus con their key competences.

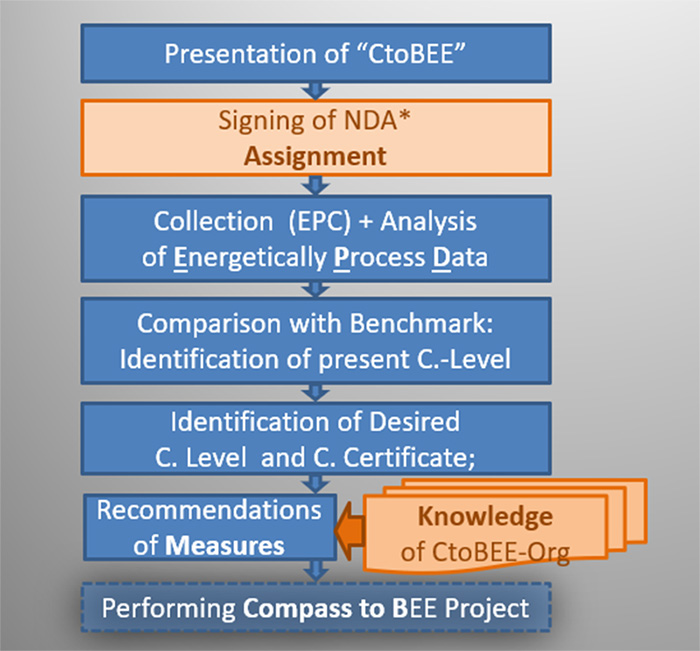

The following graphic roughly illustrates how to get started with CtoBEE coaching.

Fig.: Graphical process from first Client contact to Certification Feedback Loop

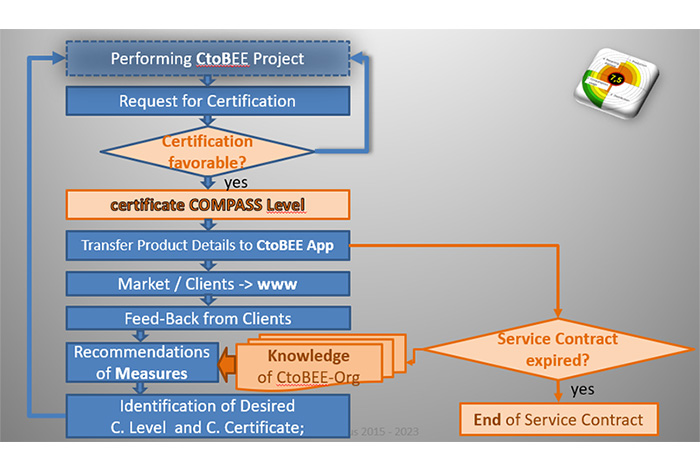

After the first CtoBEE project, the opportunity arises to enter a continuous improvement loop. An essential prerequisite for successful continuation is feedback from clients. Be it through purchase of the product or direct written or verbal feedback.

Fig.: Graphical process to Certification Feedback Loop

After having finished the first certification process, we enter in the loop for ongoing improvement.

Deduced from this process we established the CtoBEE mission statement:

CtoBEE: “Keep it simple – think straight – improve and repeat”

1. Production

There are now a large number of companies that produce and want to produce sustainably in terms of energy. Examples are shown here.

But sustainable is not identical with ecological. For ecologically sustainable production, a number of criteria would have to be met. We focus on taking the first step and finding out what is feasible in reality. For sure, this differs from company to company.

To guide the companies to focus on the essential measures the method of CtoBEE includes benchmarking.

2. Trade, Distribution

There are a number of companies that distribute and want to distribute sustainably in terms of use of energy. This area has recently gained strong attention as it is predestined for the use of visionary hydrogen technology. There are promising pilot projects. Examples are shown here.

But sustainable is not identical with ecological. For ecologically sustainable distribution, a number of criteria would have to be met. We focus on taking the first step and finding out what is feasible in reality. For sure, this differs from company to company.

3. Consumption and “Bottom-Up” approach

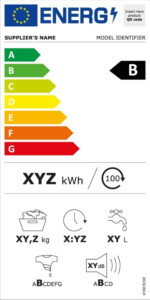

In the consumer area, we already find many certificates and seals. Examples include the Energy Consumption Label (EU 2017/1369, graded from A to G), various BIO labels for food, ‘FairTrade’ or ‘FSC’ (Forest Stewardship Council).

However, it seems that this diversity alone is becoming increasingly counterproductive, as it confuses. In order to understand the differences and objectives of the individual certificates, the customer has to deal with them intensively before selecting. He then prefers to quickly buy the cheaper or the familiar and well-known product. Simplification is needed.

With CtoBEE, all existing ones would be integrated into one figure and visually inform the customer clearly, directly and quickly. We should be clear about the fact that with the purchase decision the product cycle is decisively FEEDED: If more is bought -> more is produced and vice versa. Therefore, the genuine responsibility for a sustainable ecology lies here. It lies with us, even before it gets to politicians. And if the manufacturer knows that environmentally harmful products have no chance to be sold, he will not produce them at all. That is the “bottom up” Effect.

Here you will find information about promising ideas and projects.

4. Recycling, Disposal

The situation with recycling is chaotic. It is cheaper to produce new plastic than to reuse old one. That’s why the collected plastic is shipped in huge quantities from Europe to Asia. What happens there is certainly not in the intention of the European consumer. He assumes in good conscience that with the fee he pays for the Green Dot, the recyclable material he separates is returned to the material cycle.

More and more manufacturers are tackling the subject of ‘recycling’ in the right way: Already at the beginning of the product life cycle, the production, the end is thought of. This will happen in an even more standardized, systematic way with CtoBEE. In addition, standardization of disposal at national and international level will have advantages: The end user can dispose more easily, the disposal company receives larger quantities of similar material that can be reused more economically.

Here you will find plenty of information about the situation, suggestions for solutions and how CtoBEE would interfere.